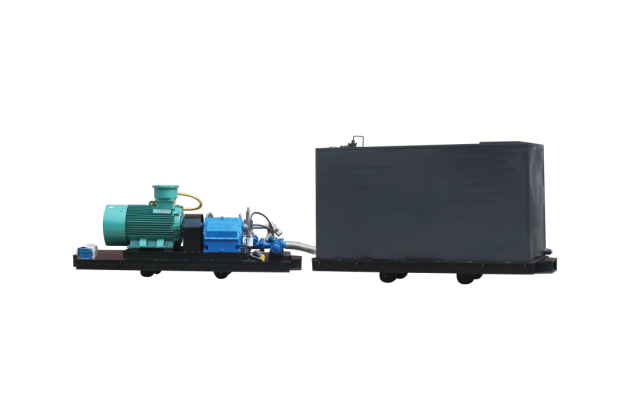

Inhibitor Pump Station

This pump uses electricity as the power drive. The process of aerosol retardant fire prevention and extinguishing involves converting a retardant aqueous solution under certain pressure into an aerosol through an atomizer. The tiny droplets sprayed by the aerosol generator can drift with the air leakage flow to any place in the goaf where air leakage occurs, thereby achieving comprehensive fire prevention in the goaf. When mining self-igniting single coal seams or multiple layered coal seams, using retardant solution for fire prevention by spraying the retardant solution onto residual coal in the goaf to suppress spontaneous combustion of residual coal is an effective method.

- Product Description

-

Inhibitor Pump Series

"Coal Mine Safety Regulations"

Article 260 Mines extracting coal seams prone to spontaneous combustion and self-ignition must prepare a special mine fire prevention and extinguishing design and take comprehensive measures to prevent spontaneous combustion of coal seams. (Comprehensive fire prevention and extinguishing measures refer to taking two or more fire prevention and extinguishing methods such as grouting, nitrogen injection, and spraying inhibitors)

"Coal Mine Fire Prevention and Extinguishing Rules"

Article 7 Coal mine fire prevention and extinguishing work must adhere to the principles of prevention first, early warning, adapting measures to local conditions, and comprehensive management, and formulate fire prevention and extinguishing measures for both surface and underground.

Mines extracting coal seams prone to spontaneous combustion and self-ignition must prepare a special mine fire prevention and extinguishing design and take comprehensive measures to prevent spontaneous combustion of coal seams. According to the specific conditions of the mine, two or more fire prevention and extinguishing technical means such as grouting, inert gas injection, and spraying inhibitors shall be adopted to implement active prevention.

Product Introduction

This pump uses electric power as the driving force. The fog inhibitor fire prevention and extinguishing process converts the inhibitor solution under certain pressure into an inhibitor fog through an atomizer. The tiny fog particles sprayed by the fog generator can drift to any air leakage area in the goaf carried by the air leakage flow, achieving all-round fire prevention in the goaf. When mining a single coal seam prone to spontaneous combustion or multiple layered coal seams, using inhibitor solution for fire prevention by spraying inhibitor solution on residual coal in the goaf to suppress spontaneous combustion is an effective method.

Product Application

This pump can pressurize the inhibitor solution and deliver it through pipelines to the goaf or high-outburst area. Using the fog generator to spray inhibitor fog into the goaf or high-outburst area achieves the purpose of preventing residual coal spontaneous combustion and fire.

Product Features

1. This equipment has a large flow and complete functions.

2. Reasonable structure and easy mobility.

3. Large liquid tank capacity allows continuous operation.

4. Atomization rate can reach over 85%.

5. Adjustable output liquid pressure and flow.

6. Equipped with a fog atomization device.

7. Capable of injecting inhibitors, can be used as a smoke elimination and dust removal pump; adding surfactants to water improves effect.

Mine Inhibitor Pump Station

Model BZ-560/24G-X560/60 BZ-665/20G-X665/60 BZ-750/20G-X750/60 Input Power Voltage (V) 660/1140 660/1140 660/1140 Motor Power (kW) 280 280 315 Outlet Pressure (MPa) 24 20 20 Flow Rate (L/min) 560 665 750 Volumetric Efficiency % ≥95 Noise dB (A) ≤87 Working Medium Inhibitor Solution Gauge 600 Weight (kg) 4300 4300 4300 Water Tank Capacity m3 6 6 6

Mine Inhibitor Pump Station

Item Flow Rate Pressure Power Device Outlet Voltage Gauge Weight Unit L/min MPa kW KJ V mm T BZ-167/15G 167 15 37 19 660/1140 600/900 1.8 BZ-50/12.5G 50 12.5 18.5 19 1.8 BZ-67/15G 67 15 18.5 19 1.8 BZ-70/27G 70 27 37 19 1.85 BZ-100/12G 100 12 30 25 1.8 BZ-125/12G 125 12 37 19 1.8 BZ-160/12.5G 160 12.5 37 19 1.8 BZ-160/16G 160 16 37 19 1.8 Item Unit BZ-200/18G BZ-250/15G BH-250/16G BZ-365/15G BZ-500/15G BZ-660/16G Flow Rate L/min 200 250 250 365 500 660 Pressure MPa 18 15 16 15 15 16 Power kW 75 75 75 110 160 200 Voltage V 660/1140 660/1140 660/1140 660/1140 660/1140 660/1140 Water Inlet Size KJ 25 25 25 25 25 Device Outlet Size KJ 51 51 51 51 51 Weight kg Note: The above products, both intelligent and non-intelligent types, can be selected according to actual conditions.

Keyword:

Online message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.