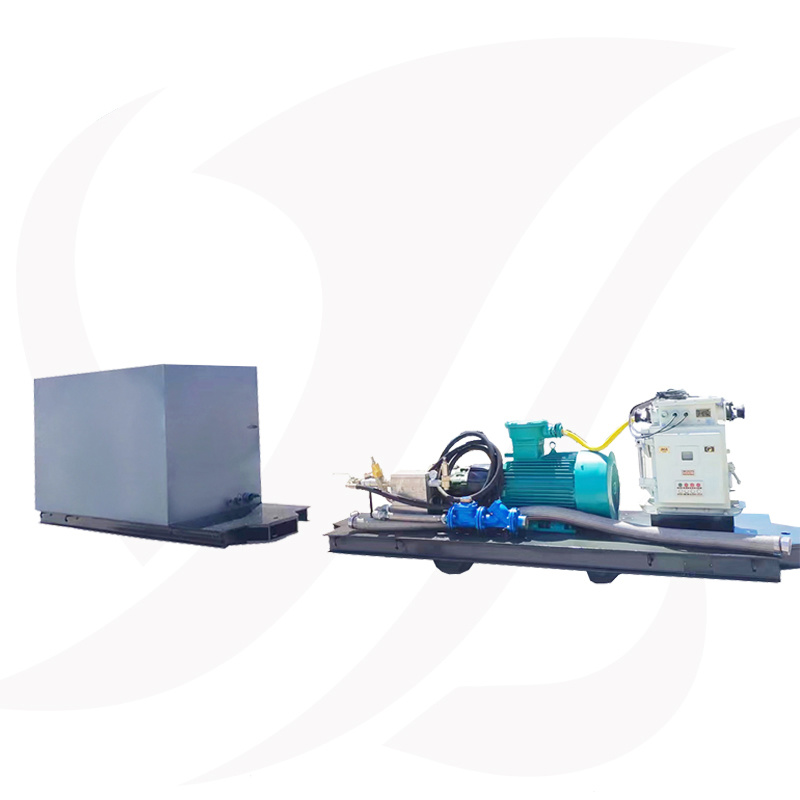

Mining-grade Inhibitor Pump Station BZ-660/16G

The mine-used flame-retardant pump station (hereinafter referred to as the flame-retardant pump) is primarily used for spraying flame-retardant agent solutions and applying flame-retardant aerosols underground in coal mines, helping to prevent spontaneous combustion of coal. When mining single or multi-seam coal seams prone to spontaneous combustion, using flame-retardant solutions for fire prevention—specifically by injecting these solutions into residual coal in mined-out areas—is an effective method to suppress spontaneous combustion of remaining coal.

View detailsThis pump uses electricity as the power drive. The process of aerosol retardant fire prevention and extinguishing involves converting a retardant aqueous solution under certain pressure into an aerosol through an atomizer. The tiny droplets sprayed by the aerosol generator can drift with the air leakage flow to any place in the goaf where air leakage occurs, thereby achieving comprehensive fire prevention in the goaf. When mining self-igniting single coal seams or multiple layered coal seams, using retardant solution for fire prevention by spraying the retardant solution onto residual coal in the goaf to suppress spontaneous combustion of residual coal is an effective method.

View detailsMining-grade flame-retardant pump

A mine-used electric inhibitor pump is a device capable of atomizing inhibitors into an aerosol form. It is used for spraying and injecting inhibitor solutions underground in coal mines, as well as for dispersing inhibitory aerosol solutions to prevent spontaneous combustion of coal. Additionally, it can function as a smoke-suppression and dust-removal pump; adding a surfactant to the water significantly enhances its effectiveness. When significant spontaneous combustion risks arise due to high roof collapses and substantial accumulations of floating coal in mine roadways, a self-made perforated iron pipe can be inserted into the collapsed area and connected to the high-pressure hose of the inhibitor pump. This setup allows the inhibitor solution to be sprayed directly onto the floating coal, effectively preventing spontaneous combustion and fire hazards.

View detailsThis pump uses compressed air as its power source and is designed for injecting inhibitor solutions and spraying inhibitor aerosols underground in coal mines, helping to prevent spontaneous combustion of coal. When mining self-igniting coal seams, the pump delivers inhibitor solutions directly to the coal face, old goaf areas, and mined-out zones, effectively suppressing residual coal from reigniting. In cases of high roof fall risks in coal roadways, the pump sprays inhibitor solutions through iron pipes onto the floating coal above the collapsed area, thereby preventing spontaneous fires. For fire prevention in mined-out areas, the pump employs atomized nozzles to deliver inhibitor fog directly onto residual coal within these regions. Importantly, this pump can be safely used in environments characterized by flammability, explosiveness, strong magnetic fields, radiation, high dust levels, extreme temperature fluctuations, and even in wet conditions.

View details