VR Simulation Training System

- Product Description

-

VR Simulation Training System

System Overview

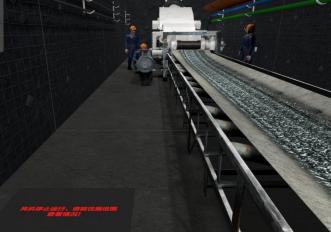

The interactive simulation training system uses a virtual reality headset as the main hardware, combined with various audio-visual sensors and other devices to block the user's external visual and auditory senses, guiding trainees to experience a realistic immersive feeling. This training system is compact and highly enclosed, providing excellent simulation effects for various underground mine environments and emergency disaster scenarios.

This system addresses the practical operation needs in training for various technical trades by using the latest virtual simulation technology for product development. It simulates coal mining, tunneling, electromechanical, transportation, ventilation, and various disaster scenarios such as roof collapse, fire, flood, and gas leaks underground. Trainees can familiarize themselves with the operation of coal mine production systems and how to handle accidents during disasters anytime and anywhere by wearing the headset, enabling special operators to master their job skills and improve practical operational abilities.

Functional Features

The training system provides production setting tools, environment setting tools, and force deduction tools within the simulation scenarios. It features a three-dimensional intuitive display and powerful interactive functions. On one hand, it enhances instructors' ability to visually and vividly teach various production processes, emergency handling methods, and precautions. On the other hand, it stimulates trainees' motivation, enhances learning experience, creates psychological immersion, and facilitates situational learning and knowledge transfer, improving trainees' enthusiasm from "I have to learn" to "I want to learn." This system effectively solves the drawbacks of traditional teaching methods being unintuitive and dull, serving as an auxiliary means to improve grassroots personnel's professional production skills and emergency handling capabilities, ensuring coal mine safety.

Using computer virtual simulation technology, the system achieves 3D visual simulation displays of mine fires, gas explosions, floods, roof collapses, dust explosions, and other disasters. It includes simulation training instructions and demonstration functions for regulated procedures and new equipment. It tests and evaluates trainees' physiological parameters, psychological endurance (equipped with a watch to monitor psychological parameters and generate analysis reports), and equipment usage. It simulates coal mining, tunneling, electromechanical, transportation, ventilation, and other systems underground, allowing trainees to familiarize themselves with the operation of coal mine production systems and how to handle accidents during disasters anytime and anywhere.

Module types include accident disaster drills, basic mine introduction, unsealing and sealing, anchor mesh support face hazard inspection, etc. It includes remote large-space multi-person collaborative command drills, voice interaction, interactive demonstrations, and other training methods. While meeting multimedia teaching and assessment for mine rescue equipment, general technical operations, medical first aid, and militarized formations, it also features a coal mine disaster 3D warning education system, mine rescue multimedia teaching system, multi-person collaborative command drill system for mine rescue, mine rescue medical first aid training system, and online mine rescue training and assessment system (including question banks collected by multiple rescue teams).

In addition to using realistic 3D effects in training scenes, the system dynamically changes temperature, wind speed, and odors according to the severity of disasters in real life. The training process can organize different rescue teams remotely via the internet for cross-regional collaborative command drills. Simulated drills include disaster area reconnaissance, casualty treatment, and disaster handling. During drills, the system can intelligently provide operational prompts.

Supports independent wireless portable VR all-in-one headset operation with inside-out self-positioning functionality. It simulates various mine tunnels and mine rescue accident site environments, allows autonomous editing of test conditions, and features six degrees of freedom position and angle positioning. It supports multiple teams walking independently or together freely in space to complete preset training processes, with training sessions lasting 30-60 minutes.

Keyword:

Online message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.