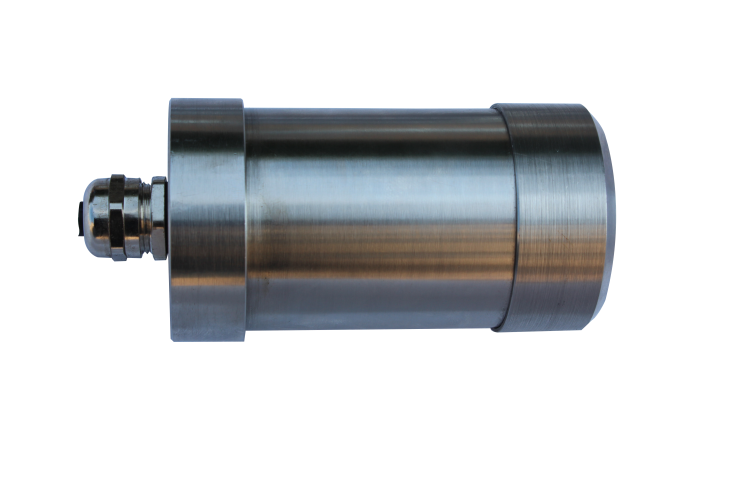

Control Box

Automatic Water Sprinkler Dust Suppression System for Mining

A large amount of dust is generated during coal mine production processes, such as during coal mining, roadway excavation, roadway support, and transportation. A comprehensive dust control system is key to ensuring effective dust management in the mine. This system uses touch sensors, sound sensors, light sensors, and thermoluminescent sensors to collect on-site environmental information, perform automatic processing and recognition, and achieve automatic spraying, reducing manual labor intensity and significantly improving dust reduction efficiency.

- Product Description

-

Automatic Water Sprinkling Dust Suppression System for Mining

Relevant Regulations

Relevant provisions in Chapter 5, Section 2 "Dust Prevention" of the Coal Mine Safety Regulations (2022 Edition)

Article 646: Underground coal mine blasting working faces shall adopt comprehensive dust prevention measures such as wet drilling, coal wall washing, water cannon mud, and coal discharge sprinkling.

Article 648: The return air roadway of the coal mining working face in underground coal mines shall be equipped with a purified airflow water curtain.

Article 649: When driving tunnels and chambers in underground coal mines, comprehensive dust prevention measures such as wet drilling, washing roadway walls and ribs, water cannon mud, blasting spray, rock (coal) sprinkling, and purified airflow must be taken.

Article 652: Underground coal bunkers (coal chutes) discharge points, conveyor transfer points and unloading points, as well as surface screening plants, crushing workshops, belt conveyor corridors, transfer points, and other locations must be equipped with spray devices or dust collectors to perform spray dust suppression or dust removal during operations.

System Overview

A large amount of dust is generated during coal mine production processes such as coal mining, roadway driving, roadway support, and transportation. A complete dust prevention system is key to ensuring effective dust control in mines. This system uses touch sensors, sound sensors, light sensors, and thermoluminescent sensors to collect on-site environmental information, automatically process and identify it, and achieve automatic spraying, reducing manual labor intensity and significantly improving dust suppression efficiency.

Functions and Uses

Different sensors can be configured to achieve various functions:

- Using touch sensors installed in transport roadways can monitor the operating status of belt conveyors. When the belt conveyor operates, it automatically controls spray dust suppression; when the belt conveyor stops, the spray dust suppression is turned off after a set delay.

- Using thermoluminescent sensors installed in return air roadways can spray to form an airflow dust filtering curtain. Dust suppression is normally on; when the sensor detects pedestrians passing by, spraying pauses and resumes automatically after they pass.

- Using sound sensors can be applied during blasting, tunneling, and coal mining. When the sensor detects blasting sounds (environmental noise intensity not less than 120dB(A)), it automatically activates spray dust suppression. When no sound is detected, spraying is turned off after a set delay.

- When the light sensor detects illumination, the main control box should control the solenoid valve to open spraying; when no light is detected, the main control box should close the solenoid valve after a delay.

- Timed spraying function: during the set spraying time period, the main control box should control the solenoid valve to open spraying; outside the set spraying time period, it should close the solenoid valve.

- Host Computer Functions: The host computer can control the underground solenoid valve to start or stop spraying, display real-time status, and query historical status.

Operating Principle of the Device

Using the clock and communication functions of the main control box combined with sensor detection signals as control signals, and the control program automatically controls the opening and closing of the explosion-proof ball valve, indirectly controlling spray start and stop.

System Features

1. Features water-saving, good dust suppression effect, and high safety.

2. Full mine networking changes the traditional product's singularity and uncontrollability. It has unified mine-wide control, visualization, manual operation, and record checking functions.

3. Selectable and adjustable modes with built-in multiple spray modes including continuous spray, continuous stop, automatic, and manual for customer selection.

4. TCP/IP mainstream transmission method, can access switches nearby via cable or optical fiber, and upload device status to the surface dispatch room.

System Applications

This water sprinkling dust suppression system is suitable for underground coal mines with gas and coal dust explosion hazards. It is mainly applied in return air roadways, belt transport roadways, tunneling roadways, and other dust-prone workplaces to purify air, improve working environment, prevent dust hazards, protect workers' health, and prevent coal dust explosion accidents.

System Components

Control Box

The mining explosion-proof and intrinsically safe automatic water sprinkling dust suppression control box can be combined individually with any of the touch sensor, sound sensor, thermoluminescent sensor, or light sensor, and applied to different working conditions or usage scenarios.

1. Has remote calibration function, allowing parameter setting, work mode selection, and delay time setting for the main control box.

2. Has the advantage of intuitive display; the LCD screen clearly shows current working status, countdown, transmission status, and other information.

3. Has TCP/IP communication function, can communicate with the host computer via network port or optical fiber interface, and form a large system network.

Touch Sensor

The touch sensor features reliable performance and ease of use. The sensor uses a vibration element to create a touch sensing circuit; when externally touched, the sensor outputs a high level, and the control box controls the opening of the solenoid valve or electric ball valve to spray dust suppression on coal cars or belts. When not touched, the sensor outputs a low level with no control operation.

Sound Sensor

The sound sensor features sensitive detection and adjustable sound volume. When environmental sound is below 90dB(A), the sound sensor outputs a low-level signal, and the solenoid valve or electric ball valve stops spraying. When noise reaches 90dB(A) or above, the sensor outputs a high-level signal, and the control box controls the solenoid valve or electric ball valve to start spray dust suppression.

Light Sensor

The photoelectric sensor features high sensitivity, simple adjustment, and ease of use. The sensor uses a photosensitive element to design the signal acquisition circuit; when light is detected, the photosensitive element outputs a high-level signal, which is processed by the signal processing circuit and transmitted to the control box. The control box then controls the electromagnetic valve or electric ball valve to open for mist dust suppression. When there is no light, the sensor outputs a low-level signal with no control operation.

Thermoluminescent Photoelectric Sensor

The thermoluminescent photoelectric sensor features sensitive detection, high reliability, and easy installation. The sensor mainly uses the principle of human body induction to control mist dust suppression in tunnels, ensuring pedestrians are not sprayed. It is mainly used in intake and return air tunnels, main haulage tunnels, and coal storage yards.

Main Technical Parameters

Control System

1. System power supply voltage: AC127V

2. Voltage fluctuation range: 75% to 110% of nominal value

3. System capacity:

(a) The system can connect up to 20 main control boxes.

(b) Each main control box has 4 switch input channels. Channels 1, 2, and 3 can connect touch, sound, or light sensors (modifiable via LCD menu); channel 4 can connect a thermoluminescent photoelectric sensor (also modifiable via LCD menu).

(c) Each main control box can connect 1 electromagnetic valve; each electromagnetic valve can connect multiple nozzles.

(d) Electromagnetic valve pressure operating range: 0.2 to 10 MPa.

Main Control Box

(a) Rated operating voltage: AC127V

(b) Rated operating current: ≤200mA

(c) Input signal: When the input is ≥3.0VDC high-level signal, it should change the control state of the main control box; when the input is ≤0.5VDC low-level signal, it should restore to the initial state after a delay.

(d) Action hold time: adjustable from 10s to 999s

(e) Allowed time setting error: ±3s

(f) Power fluctuation: power supply between 75% and 110%

(g) Transmission distance: cable transmission distance from sensor to main control box is 2 km

Touch Sensor

Operating voltage: DC12V.

Operating current: ≤30mA.

Output Signal

- When the sensor is externally triggered, it outputs a high-level signal; when there is no external trigger, it outputs a low-level signal.

- High and low-level switch signals: high level not less than 3V (pull-out current 2mA), low level not more than 0.5V. c) Number of output channels: 1; d) Transmission distance: cable transmission distance from sensor to main control box is 2 km (simulation cable parameters: k=12.8Ω/km, L=0.8mH/km, c=0.04μF/km).

Thermoluminescent Photoelectric Sensor

Operating voltage: DC12V.

Operating current: ≤30mA.

Output Signal:

a) When the sensor detects someone passing within the sensing area, it outputs a high-level signal; when no one passes, it outputs a low-level signal.

b) High and low-level switch signals: high level not less than 3V (pull-out current 2mA), low level not more than 0.5V.

c) Detection distance: ≤5m;

d) Detection range: ≤50°;

e) Number of output channels: 1;

f) Transmission distance: cable transmission distance from sensor to control box is 2 km (simulation cable parameters: k=12.8Ω/km, L=0.8mH/km, c=0.04μF/km);

Light Sensor

Operating voltage: DC 12 V.

Operating current: ≤30 mA.

Transmission distance: cable transmission distance from sensor to main control box is 2 km.

When there is light, the sensor outputs a high-level signal; when there is no light, the sensor outputs a low-level signal.

Sound Sensor

Operating voltage: DC 12 V.

Operating current: ≤30 mA.

Transmission distance: cable transmission distance from sensor to main control box is 2 km.

When noise reaches 120dB(A), the sensor outputs a high-level signal; when below 120dB(A), it outputs a low-level signal.

- Using touch sensors installed in transport roadways can monitor the operating status of belt conveyors. When the belt conveyor operates, it automatically controls spray dust suppression; when the belt conveyor stops, the spray dust suppression is turned off after a set delay.

Keyword:

Online message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.