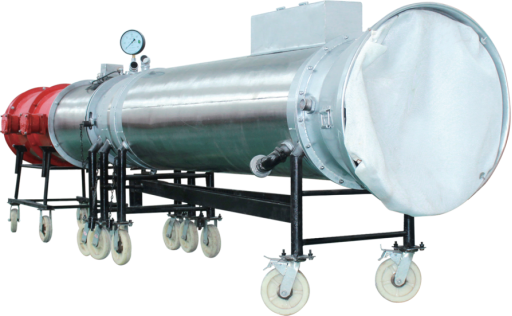

Fuel Oil Inert Gas Foam Generator for Mining

The inert gas foam generator for mining is an advanced technological device primarily used for fire suppression in underground coal mines. It can rapidly inert the fire zone, effectively prevent gas explosions, and significantly reduce or eliminate the risk of residual fire re-ignition. This device integrates inert gas and high-foam technologies, featuring dual functions of isolation cooling and releasing suffocating inert gases, ensuring more thorough fire extinguishing and quickly restoring safety to the work area. The device supports compatibility with inert gas and inert foam, can monitor oxygen levels in real time, and adjust gas composition, enhancing automatic protection functions during water shortage and power failure. Additionally, it is equipped with a secondary combustion device to ensure that carbon monoxide levels remain low even when oxygen concentration decreases. The device uses imported oxygen sensors that can be used long-term without replacement.

- Product Description

-

Mine-use Fuel Inert Gas Foam Generator

Product Introduction

The mine-use inert gas foam generator is an advanced technical device mainly used for fire fighting in underground coal mines. It can quickly inert the fire area, effectively suppress gas explosions, and significantly reduce or eliminate the risk of residual fire re-ignition. This device integrates inert gas and high-foam technology, featuring dual functions of isolation cooling and releasing suffocating inert gas to ensure more thorough fire extinguishing and rapid restoration of safety in the work area. The device supports the versatility of inert gas and inert foam, can monitor oxygen content in real time, and adjust gas composition, enhancing automatic protection functions during water shortage and power failure. Additionally, it is equipped with a secondary combustion device to ensure that carbon monoxide levels remain low even when oxygen concentration decreases. The device uses imported oxygen sensors that can be used long-term without replacement.

Product Features

- Adopts combined inert gas and high-foam fire extinguishing technology, combining high-foam isolation cooling and inert gas suffocation for thorough fire extinguishing;

- Quickly inert the fire area, control gas explosions, and reduce or eliminate residual fire re-ignition.

- Features high-foam isolation cooling and oxygen dilution, and releases suffocating inert gas after foam breaking, providing multiple effects such as inerting, suffocating, and explosion suppression in the fire area;

- Prevents residual fire from easily re-igniting, ensures thorough fire extinguishing, and allows quick work resumption.

- Freely extendable and retractable, newly redesigned automatic leveling shock-absorbing wheels, whole machine made of stainless steel.

- Can form different fire extinguishing models according to fire changes, achieving multi-purpose use with one machine.

Main Technical Parameters

Item Unit DQP-100 DQP-200 DQP-500 Inert Foam Output m³/min 80~100 150~200 400~500 Inert Gas Volume m³/min 130~150 400~500 800~1000 Air Foam Output m³/min 80~100 200~230 450~500 Fuel Consumption kg/min 4~5 7~13 21.7~28.5 Water Consumption m³/h 15 30 50 Foaming Agent Concentration % 3~6 3~6 3~6 Inert Gas Composition % O₂≤5 O₂≤5 O₂≤5 Total Length m 6.5 10 14 Weight kg 2400 2900 3400 Power kw 11.5 30.5 47.5

- Adopts combined inert gas and high-foam fire extinguishing technology, combining high-foam isolation cooling and inert gas suffocation for thorough fire extinguishing;

Keyword:

Online message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.